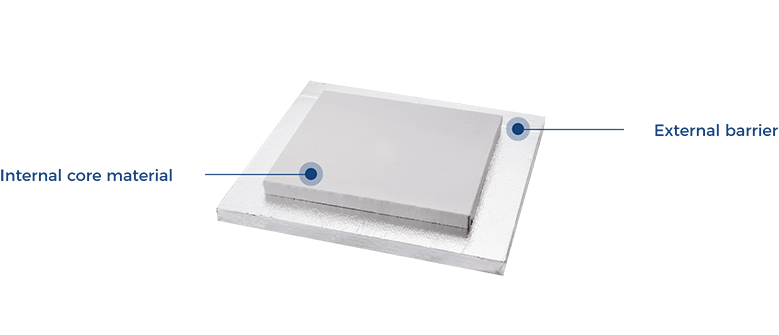

Vacuum insulation panels (VIPs) are a type of insulation material that offer extremely high thermal resistance in a very thin profile. Vacuum insulation panels consist of two main components: the core material and the film. The air is then evacuated to creat a vacuum state inside. This vacuum greatly reduces heat transfer by convection and conduction, resulting in a highly effective insulation material.

VIPs have a very low thermal conductivity, typically < 0.005 W/m·K. This is significantly better than other insulation materials such as fiberglass, mineral wool and or foam board, which typically have thermal conductivities ranging from 0.03 to 0.04 W/m ·K. As a result, VIPs are used in applications where high thermal efficiency is required, such as in building insulation, refrigeration, and transportation.

· Gas-tight barrier film

· Sealed against air and water vapor

· Fleece envelope

· Core material of fumed silica and opacifier

BUILDING INSULATION

VIPs are used to insulate walls, roofs, floors, and other building components.They can significantly reduce heating and cooling costs and improve energy efficiency in buildings.

TRANSPORTATION

VIPs are used in containers, trucks, and other transport vehicles to insulate heat or cold-sensitive cargo, such as food, pharmaceuticals, or chemicals.

REFRIGERATION

VIPs are used in refrigerators, freezers, and cold rooms to maintain consistent temperatures and reduce energy consumption.

INDUSTRIAL APPLICATIONS

VIPs are used in various industrial applications, such as boilers, pipelines and tanks, to insulate against heat loss and reduce energy consumption.